How to Switch to Eco-Friendly Shopping Bags Without Disrupting Your Process

Most factories and retail operations today already run at full stretch. Production timelines are tight. Approvals move through layers. And SOPs are designed to avoid surprises.

In that environment, even a small packaging change can feel risky. Switching to eco‑friendly shopping bags is often described as a simple decision. In practice, it rarely is. The moment the conversation starts, a few realities come up.

For starters, you don’t use just one type of bag. There are shopping bags, garments, inner polybags, and liner bags.

Secondly, compliance has become stricter across India, the US, and the EU, especially for bioplastic-related products.

Cost is another crucial factor. Most businesses that are trying to reduce overhead would automatically worry that switching to eco-friendly alternatives would cost more.

Lastly, there is very little room for trial‑and‑error once production or sourcing is locked in.

Most businesses delay the switch because they don’t want to disrupt what already works. But disruptions come from switching without:

- A clear structure

- Clarity on compliance

- Testing how the bags behave in real conditions

When those pieces are thought through in advance, the transition becomes seamless.

Hesitation #1: “We use many types of packaging. How do we switch everything together?”

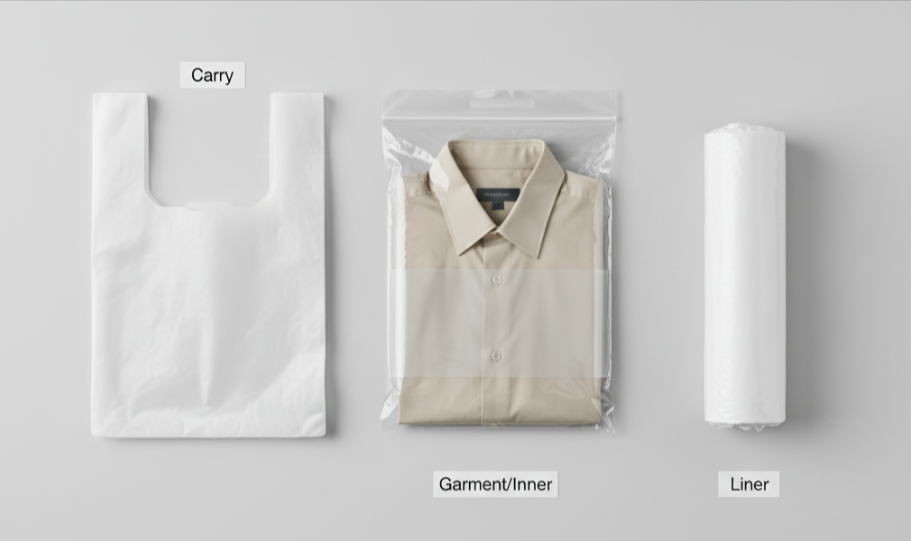

This is usually where the conversation gets stuck. Very few businesses use a single type of shopping bag. In most cases, there’s a mix of:

- Carry or checkout bags

- Garment or inner polybags

- Liner bags for storage and transport

Each serves a different purpose. Each has different strengths, thickness, and sealing requirements.

So when someone suggests switching to eco‑friendly shopping bags, the instinctive response is to do it gradually. Start with one category. Test the rest later.

That approach looks safe on paper. In practice, it creates more problems. You often end up managing multiple suppliers. Compliance documentation looks fragmented. And internal teams struggle with inconsistent specs and timelines.

Instead of reducing complexity, the switch increases it. The cleaner way is to look at packaging as a system, not a collection of isolated products.

What matters most at this stage is not the type of bag, but the kind of supplier you work with. Avoid setups where one vendor only resells finished bags. Or, another that specialises in just one narrow format, like garment covers.

What works better is a single converting manufacturer that can support all your major bag formats. They should also use the same compliance framework and quality approach.

That means the supplier should be able to:

- Manufacture compostable shopping bags, garment bags, and liners using consistent specifications.

- Optimise thickness and seal strength per use case without over‑engineering.

- Provide uniform documentation across all bag categories.

At Murth, this is exactly how we approach the transition. We don’t ask teams to rethink their packaging in fragments. We help them replace entire bag families together.

Hesitation #2: “What if we switch and later find it’s not actually eco‑friendly?”

On paper, many bags are marketed as green, eco-friendly, or biodegradable. In reality, not all of them will stand up to an audit.

Some fail on certification. Others fail on labelling. A few pass tests, but only under conditions that don’t match how the bags are actually used or disposed of.

For brands, retailers, and manufacturers, this creates a reputational and compliance risk. That’s why it’s important to be very clear about what “eco‑friendly” actually means in practice.

For shopping and garment bags, regulators look at standards, test reports, and documentation.

In India, compostable shopping bags must meet CPCB certification requirements. That includes approved test reports and mandatory markings printed directly on the bag.

In the EU, compostability claims are typically tied to EN 13432. In the US, ASTM D6400 is the reference point for compostable plastics.

If a supplier can’t clearly explain which standard their product complies with or show evidence for each bag format, you’re already taking a risk.

Over the years, I’ve found that a short due diligence checklist works better than any brochure. Before switching to biodegradable shopping bags, these five questions should always be answered clearly:

- Are the bags and the materials you’ve used certified?

- Can you present the actual test reports?

- If there’s an issue later, can we trace which batch our bags came from?

- Are all the required details printed on the bag as per the rules? Or, do we need to add anything ourselves?

- Will the same compliance apply to all our bag types? Or, does each one need separate approvals?

If the answer to any of these is vague, the problem will likely show up later.

At Murth, we treat compliance as a format‑specific exercise. Our eco‑friendly shopping bags, garment polybags, and liners each carry their own CPCB certification and markings. Documentation is maintained per category, not bundled loosely under a generic claim.

Hesitation #3: “Will my team need to change their process or handling?”

Most businesses have this concern. What if the new bags need different temperatures for sealing? Or, don’t have the same clarity or feel? Or, slow down packing or stacking on the line?

The fear is real because most production teams have built routines around LDPE or traditional plastics. Any deviation, even a minor one, can cause slowdowns, confusion, or mistakes.

Here’s the reality. When compostable or biodegradable shopping bags are designed well, they’re made to fit into the same processes as your existing bags.

That means sealing is done on the same machines, with no major changes to temperature settings. The bags maintain clarity and handle just like your current bags. They stack, pack, and move through your operation with no surprises.

In the rare cases where there’s a small difference, a good biodegradable plastic bags supplier will guide your team through it.

At Murth, we provide on-floor training or remote support for any tweaks needed, but these are almost always minimal.

Hesitation #4: “Finance will never approve the cost.”

Almost every packaging switch hits this question sooner or later: “Isn’t eco-friendly going to cost us more?”

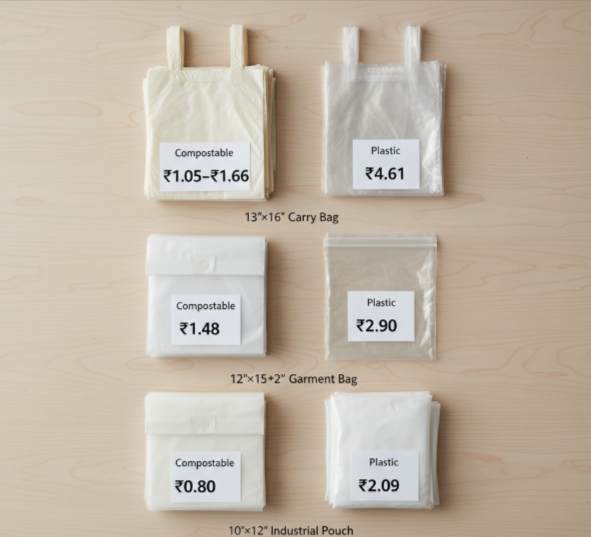

It’s a fair concern. For a long time, eco-friendly shopping bags really did carry a premium. But that’s changing fast, and the numbers prove it.

Let’s take a simple, common example. A standard 13″ x 16″ compostable carry bag today typically costs between ₹1.05 and ₹1.66 per piece. Traditional plastic carry bags of the same size cost around ₹4.61 per piece.

The eco-friendly option now costs less than half as much as the plastic version. And this isn’t just about carry bags. It applies across the board:

| Product Type | Compostable Bag | Traditional Plastic Bag |

| Transparent Garment Bag (12″x15″+2″) | ₹1.48 per piece | ₹2.90 per piece |

| Industrial Pouch (10″x12″, opaque) | ₹0.80 per piece | ₹2.09 per piece |

So, if you’re distributing 1,000 bags a month, that’s a direct saving of over ₹3,000 every month just by switching to compostable bags. You won’t have to change your workflow, your staff, or your equipment.

Where do these savings come from?

- Direct manufacturing (no markup stacking).

- Local sourcing and material optimization.

- Smart design to match thickness and performance with what you already use.

The hidden costs of “cheap” plastic bags include failed audits, non-compliance penalties, and reputational risk. These can quickly wipe out any short-term savings.

In India, falling short on CPCB requirements can mean halted shipments. In the EU and US, using bags that don’t meet compostability or labelling standards can mean fines or lost business.

Getting started without risk: MOQ and pilot runs

Once the decision is made, the next hurdle is always: “How do we switch without risking everything at once?”

Don’t go all in on day one. The safest way to transition to eco-friendly reusable shopping bags is to start with a pilot run. This is how most successful teams do it:

- Begin with one bag type (usually your highest-use shopping bag).

- Set a small minimum order quantity (MOQ) for the first batch.

- Test the bags in your real operation.

- Validate the documents related to compliance.

Once you’re confident, you can think of expanding to other products in phases. Use each round of feedback to smooth out any minor tweaks or adjustments.

At Murth, we always recommend phased adoption with flexible MOQs. You get to validate performance before scaling up. And you have our support at every stage. There are no gambles involved. All you get is a practical and measurable change.

Final thoughts

Ready to move forward?

Start by reviewing your current bag categories and volumes. Reach out to suppliers who provide all key formats. Make sure they follow compliance thoroughly.

Ask for pilot runs with flexible MOQs. Check certificates, test reports, and actual bag markings before scaling up. Involve your floor teams early for feedback, and train them on any minor process tweaks.

When you follow these steps, switching to eco-friendly shopping bags becomes a predictable, low-risk, and rewarding process for your business.