The Shift Every Importer Is Talking About

Walk through any supermarket aisle or scroll through an e-commerce unboxing video, and you’ll see it: packaging is getting lighter, sleeker, and smarter.

Rigid plastics and cardboard are being replaced by flexible formats — films, pouches, and courier mailers that use less material and ship more efficiently. But as global bans on single-use plastics tighten, a crucial question has emerged:

Can flexible packaging be sustainable too?

The short answer — yes. And compostable flexible packaging is leading that transformation.

For importers, especially those sourcing from Asia, this evolution is more than a design trend — it’s a strategic shift in trade economics, compliance, and customer perception.

Let’s unpack how flexible compostable packaging is redefining the future of global trade — and why India, with innovators like Murth, is fast becoming its epicenter.

1. The Global Shift: Why FMCG & E-Commerce Are Going Flexible

Lighter, Leaner, and Faster

The global packaging industry has entered a “flexibility revolution.” Industry reports project the flexible packaging market in the low-to-mid hundreds of billions by 2030; estimates vary (e.g. Allied Market Research: $325.8B by 2032 at ~5.1% CAGR).

The surge is powered by two major sectors:

- FMCG, which seeks lightweight formats for snacks, personal care, and refills.

- E-commerce, which demands durable yet space-efficient courier packaging.

As brands move to meet sustainability goals, the focus isn’t just on recyclability — it’s on reducing total material use.

Flexible packaging offers up to 60–70% lower material consumption than rigid alternatives. That means smaller carbon footprints across shipping, warehousing, and disposal.

The Compostable Revolution

Traditionally, flexible packaging has relied on multi-layer plastics — often unrecyclable because of mixed polymers. But with next-gen compostable films and biopolymers, flexibility no longer conflicts with responsibility.

Materials like PLA (polylactic acid), PBAT (polybutylene adipate terephthalate), and bio-based starch blends now mimic the strength and clarity of traditional plastic while decomposing naturally under composting conditions.

Governments have noticed too.

- The EU Packaging and Packaging Waste Regulation (PPWR) now requires all packaging to be recyclable or compostable by 2030.

- India’s Plastic Waste Management (PWM) Rules 2022 provide regulatory incentives for compostable alternatives and have supported domestic capacity growth

- The U.S. FTC Green Guides update (2024) has reviewed its Green Guides and proposals for clearer labeling are ongoing; brands should track FTC guidance and state-level actions.

In short, flexible compostable packaging isn’t niche anymore — it’s becoming regulatory default.

2. Market Trends Driving Flexible Compostables

a. Sustainability Mandates Are Tightening

Regulations across Europe, the U.S., and Asia are directly targeting non-compostable flexible plastics. Retailers like Tesco and Carrefour have pledged 100% sustainable packaging by 2025.

For importers, that means suppliers who can’t offer ASTM D6400 / EN 13432-certified compostable options will be phased out of global supply chains.

b. E-Commerce Packaging Is the New Sustainability Frontier

A single e-commerce shipment may travel thousands of kilometers — from manufacturer to port, to fulfillment center, to doorstep. Every gram saved compounds across millions of parcels.

That’s why e-commerce majors like Amazon and Flipkart are piloting compostable mailers, pouch refills, and thin-gauge films that balance performance with planet impact.

c. Consumer Sentiment Has Turned the Tide

Consumers say they’re more likely to buy from brands using eco-friendly packaging — and are willing to pay more for it.

In markets like Europe and the Middle East, compostability adds tangible brand equity. A “100% compostable” logo on your packaging isn’t simply compliance, it’s storytelling.

d. Cost Parity Is Near

Compostable flexible films were once more expensive than plastic. But feedstock innovation in India (using corn starch, bagasse, and cassava) has reduced cost gaps dramatically.

As global resin prices fluctuate and carbon taxes expand, compostable films are approaching price parity for many SKUs — particularly courier mailers, laminates, and flow wraps.

3. Why Importers Prefer Flexible Compostable Packaging

For global importers, the appeal of compostable flexible packaging goes beyond eco-credentials. It’s about efficiency, compliance, and differentiation.

1. Optimized Shipping & Storage

Flexible packaging drastically reduces freight volume and weight.

- Much lower shipping costs compared to rigid alternatives.

- Higher container yield (more units per cubic meter).

- Lower warehousing and fuel footprint.

When compounded across annual import volumes, the cost savings are significant.

2. Regulatory Peace of Mind

Compostable flexible packaging automatically addresses multiple compliance challenges:

- Meets EU EN 13432 and US ASTM D6400 compostability standards.

- Avoids import bans under the EU Single-Use Plastics Directive (SUPD).

- Simplifies customs clearance by providing clear, certified documentation.

Importers dealing with large retail chains or government tenders also find compostable certifications reduce audit risks and rejection rates.

3. Branding & Shelf Appeal

Flexible compostables now offer premium-grade printability, gloss, and tactile finishes comparable to plastic films.

With global packaging moving toward “eco-luxury,” importers can deliver both sustainability and aesthetics — matte finishes, natural tones, and organic textures that reinforce brand values.

4. End-of-Life Advantage

Unlike “biodegradable” plastics that can persist for years, certified compostable flexible packaging fully breaks down in controlled environments (industrial composters).

This gives importers and brands a verifiable sustainability claim, validated by testing agencies like TÜV Austria or DIN CERTCO.

5. Cost Predictability

As oil-linked plastic resins face volatile pricing, compostable biopolymers sourced from renewable, agricultural feedstocks are more stable.

India’s domestic availability of starch, bagasse, and other biomass materials keeps pricing consistent — a major advantage for long-term import contracts.

4. The Product Landscape: What Flexible Compostables Look Like

Compostable flexible packaging isn’t one product. It’s a spectrum of formats tailored for specific use cases.

1. Compostable Courier Bags

A mainstay of global e-commerce.

- Strong, tear-resistant, waterproof.

- Printable with brand logos.

- Certified to EN 13432 / ASTM D6400.

- Available with adhesive flaps, double seals, and writable surfaces.

Ideal for fashion, electronics, and lifestyle goods — offering the same convenience as LDPE mailers without the environmental burden.

2. Food & FMCG Pouches

Flexible pouches dominate FMCG shelf space. Compostable variants now support:

- Dry snacks, coffee, tea, powders, refills

- Barrier-coated compostable films for moisture and oxygen protection

- Heat-sealable and resealable formats

Innovations in bio-based barrier coatings mean importers can now replace PET or aluminum layers while maintaining shelf life.

3. Compostable Films & Wraps

Thin-gauge compostable films are replacing polybags, wraps, and overpacks.

- Perfect for fresh produce, bakery items, or secondary packaging.

- Printable, clear, and puncture-resistant.

- Available in home- and industrial-compostable grades.

For importers, these are low-MOQ entry points into compostable sourcing, ideal for pilot runs or new product launches.

4. Laminates & Multi-Layer Compostables

Advancements in material science now enable compostable multi-layer laminates with mechanical performance on par with plastic.

Used for liquid pouches, refill packs, and cosmetic sachets, they demonstrate that sustainability doesn’t mean compromising on functionality.

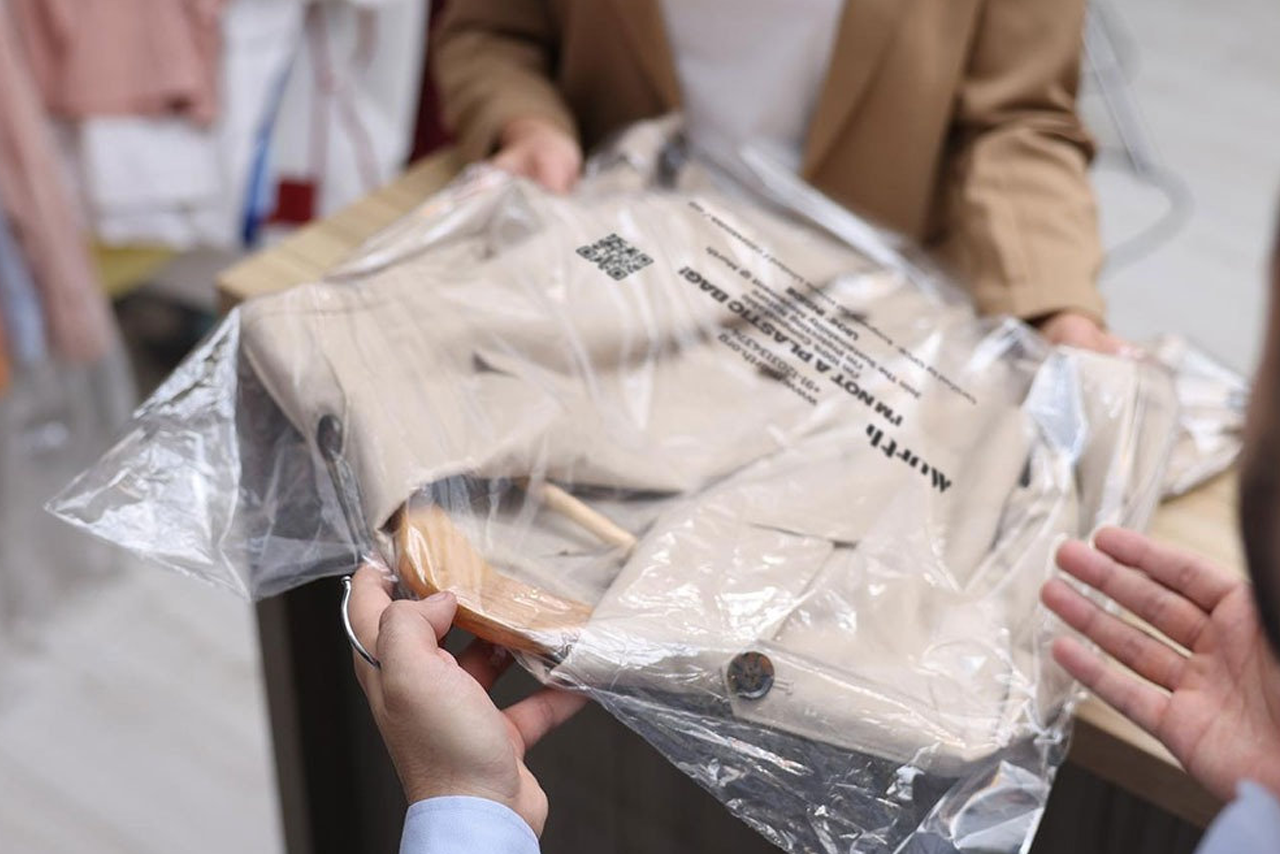

5. Murth’s Advantage: India’s Leading Flexible Compostable Packaging Supplier

While global demand for flexible compostables rises, Murth is ensuring India stays ahead of the curve.

Here’s what sets Murth apart:

Certified & Globally Compliant

Murth’s flexible compostable packaging is certified under leading international standards:

Each batch is backed by traceable documentation ensuring importers clear audits and customs seamlessly.

Material Innovation, Locally Sourced

Murth leverages India’s agricultural ecosystem to create bio-based films and resins from bagasse, corn starch, and other natural residues.

This localized sourcing minimizes carbon footprint and price volatility while supporting rural circular economies.

Flexible Formats, Global Reach

Murth manufactures across key categories:

- Compostable courier bags & mailers

- Pouches & sachets for FMCG

- Flow wraps, films, and liners

- Custom flexible packaging for private labels

Technical Expertise & Transparency

Murth doesn’t just sell packaging. It partners with buyers to ensure success.

- Pre-shipment compliance documentation

- Batch-wise test reports & certification copies

- Responsive English-speaking export team

This level of transparency is rare in the packaging sector — and it’s why global importers trust Murth to represent India’s best.

Scalable Manufacturing & Reliable Delivery

Murth’s production capacity supports both small-volume trial orders and high-volume export shipments.

Shorter lead times and strategically located manufacturing units reduce turnaround and freight costs.

Future-Ready Innovation

Murth is continuously investing in:

- High-barrier compostable laminates

- Bio-based printing inks

- Compostable zipper and valve systems

For importers planning future-proof portfolios, this innovation pipeline ensures long-term compatibility with evolving global standards.

6. Why Importers Are Switching to Murth’s Flexible Compostables

| Buyer Concern | Traditional Plastic | Murth’s Compostable Flexible Packaging |

| Sustainability | Non-biodegradable, landfill waste | 100% compostable and following required certifications |

| Shipping Efficiency | Bulky, higher weight | Lightweight, compact, cost-saving |

| Brand Appeal | Outdated perception | Eco-premium, modern design |

| Regulatory Compliance | At risk under EU/US bans | Fully compliant, documentation ready |

| Traceability | Often opaque | Batch-level test certification |

| Cost Predictability | Oil-linked fluctuations | Stable, bio-based input pricing |

Murth combines all the advantages importers seek — sustainability, compliance, and cost efficiency — in a single reliable supply partner.

7. The Future Is Flexible — and Compostable

As global trade pivots toward circularity, flexible compostable packaging stands out as the bridge between performance and planet.

- It saves costs across logistics and warehousing.

- It meets stringent international compliance benchmarks.

- It delivers on the sustainability story of today’s consumer demand.

India, once a follower in packaging innovation, is now setting the benchmark — and Murth is at the forefront of that transformation.

From the world’s factories to the world’s future, Murth makes flexibility sustainable.

Request a Sample, Experience the Difference

If you’re an importer or brand looking to switch to eco-friendly flexible packaging that checks every box — performance, compliance, and cost — it’s time to explore Murth’s range.

Request free samples or product specs today and discover why leading importers are making the switch to Murth’s compostable flexible solutions.

Because in 2025 and beyond, the future of packaging isn’t just flexible — it’s responsibly compostable.

Sources

alliedmarketresearch.com/press-release/flexible-packaging-market.html

https://www.marketsandmarkets.com/Market-Reports/flexible-packaging-market-report-162180170.html

https://www.pregis.com/knowledge-hub/rigid-vs-flexibles-time-to-make-the-switch/

https://www.tescoplc.com/media/wvkj1yic/tesco-sustainability-report-2025.pdf

https://www.packagingdive.com/news/packaging-labeling-recyclable-compostable-green-guides/738514/