Common Mistakes When Sourcing Compostable Bags in India

With regulations getting stricter, most businesses today are actively trying to move away from conventional plastic.

Yet, for many organisations, sourcing compostable bags in India often turns out to be more complicated than expected.

The market is crowded with overlapping claims like biodegradable, eco‑friendly, green plastic, many of which mean very little in practice.

Certifications are shared, but not always understood. Prices are compared using the wrong benchmarks.

And decisions that are meant to reduce risk sometimes introduce new ones, like compliance issues, supply instability, or unexpected costs.

From what I’ve found in my years in the industry, the problem is rarely the material itself. Certified compostable bags work when they are sourced correctly. Most issues arise at the sourcing stage itself.

Let us look at some of the common mistakes businesses make when sourcing compostable bags in India.

Mistake #1: Assuming biodegradable means compostable

Whether you search online or talk to suppliers, you’ll often hear the terms “biodegradable” and “compostable” used almost interchangeably. They may sound similar. But they actually mean very different things under the law.

Biodegradable:

In practice, this label is often used for plastics with additives that help them break into smaller fragments. The catch here is that most of these bags don’t fully disappear and often leave microplastics behind.

Compostable:

Compostable bags are designed to break down completely over time. In industrial composting systems, these bags turn into water, CO₂, or soil. And the process doesn’t leave any toxic residue behind.

In India, only plastic bags that meet the IS/ISO 17088 standard and are certified by the CPCB count as compostable.

Why does this matter? Using the wrong bag can land you in legal trouble and damage your credibility. And it harms the environment in the end.

Mistake #2: Not checking what the certification actually covers

You need to know which certifications actually matter. I’ve seen many buyers request a certified bag. They receive a document and assume everything is sorted.

But there’s a crucial detail most overlook. What does the certification actually cover? That’s where things get a little more complicated.

Sometimes, suppliers show a certificate for the raw material, say, a resin that is technically compostable on its own. But what truly matters is certification for the finished bag, after it’s been extruded, printed, and cut to your specifications.

If the bag is made from certified resin but gets extra additives, dyes, or is manufactured below the standards, it may no longer qualify as compostable.

Worse, many suppliers show expired certificates, certificates issued to a different manufacturer, or simply a generic “eco-friendly” label.

To stay compliant, always check that:

- The supplier is listed on the CPCB’s official registry.

- The certificate is valid and current.

- The certificate matches the supplier’s name and bag type.

- The finished product has the CPCB registration number.

Checking these things early on can help you avoid fines and legal troubles later on.

At Murth, we take certification seriously. Every compostable bag we supply is backed by up-to-date CPCB documentation. Our clients receive not just certificates, but actual verification of compliance. That makes audits and regulatory checks seamless.

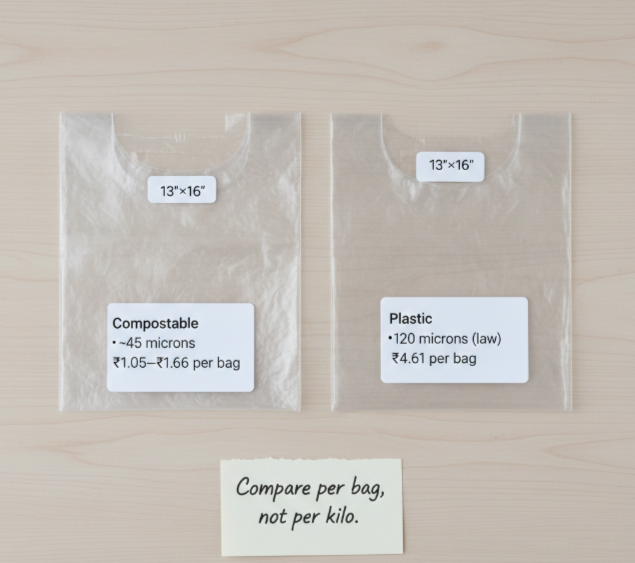

Mistake #3: Comparing cost on a per-kilo basis instead of a per-unit basis

On paper, compostable bags may look far more expensive than plastic. That’s because most buyers instinctively compare the price per kilogram. It’s a habit carried over from traditional plastics procurement.

But there’s a catch in this. In India, plastic carry bags must be at least 120 microns thick by law. This regulation means each plastic bag is heavier, so you get fewer bags per kilo.

Compostable carry bags in India, however, are exempt from this thickness rule. They can be produced much thinner as long as they still serve the intended purpose.

Let’s break down how it impacts cost:

Suppose you’re sourcing bags for lightweight garments. A 120-micron plastic bag might yield just 70–80 pieces per kilo. A compostable bag at 40–50 microns could yield more than 200 pieces per kilo.

Even if the compostable resin costs twice as much per kilo, the cost per usable bag can be the same or even lower.

| Bag Type | Compostable Bag (₹/pc) | Plastic Bag (₹/pc) |

| Carry Bag (13″ x 16″) | 1.05 – 1.66 | 4.61 |

| Garment Bag (12″ x 15″+2″) | 1.48 | 2.90 |

| Industrial Pouch (10″ x 12″) | 0.80 | 2.09 |

So, what does this mean?

Switching to compostable can actually cost less. For a retailer using 1,000 bags a month, that’s a direct saving of over ₹3,000 every month.

Don’t focus on the price per kilo. Focus on the price per usable bag for your real application. That’s where the real savings and impact are found.

Mistake #4: Not creating a clear inventory of bag types beforehand

Another common mistake is not accounting for all the different types of bags you need.

No two businesses have the same requirements. Some may only need carry bags for retail counters. Others might require garment sleeves for apparel, or courier bags for shipping online orders.

If you approach a supplier with a vague request like “we need compostable bags,” you risk two things. First, you may end up paying for features you don’t need. Or, you may have performance-related issues like using a thin garment bag as a garbage liner. It will inevitably tear or leak.

The fix is simple. Before you start, make a simple list based on the following questions:

- What do you need the bags for?

- What sizes and weights do they need to handle?

- Are handles, transparency, or custom printing required?

Based on these details, compostable bags suppliers in India will recommend cost-effective options.

Mistake #5: Failing to negotiate based on total order volume

A common mistake buyers often make is that they treat each bag type as a separate deal. Let’s say you negotiate SKU by SKU. So, you negotiate for carry bags this month, courier bags next quarter. Doing this, you lose out on the pricing power that comes with total volume.

Suppliers tend to offer better terms when they understand your total volume. Grouping different bag types together allows you to secure better pricing across orders.

A simple conversation early on can make negotiations much easier. You can say something like, “Here’s our estimated annual or quarterly demand. Can you offer estimates for the full basket?”

Mistake 6: Not setting a benchmark for expected quality

I regularly see buyers approve a sample, place an order, and assume every future batch will look and perform the same.

But if you don’t set a clear benchmark for quality, you may see slight variations with each order. It can be a slightly thinner film, weaker seals, or an inconsistent finish. It will cause a lot of frustration, but you’ll have no clear basis to push back.

Before approving production, you should define a few basics in writing:

- Target thickness with a clear tolerance range.

- Acceptable variation in size and finish.

- Minimum performance expectations.

- What will count as a reject.

- At what defect level can a batch be refused.

When quality expectations are agreed upfront, suppliers know exactly what they’re accountable for. And you can avoid arguments later that can disrupt supply.

At Murth, we spend time understanding detailed requirements upfront, so expectations are clear before production begins.

Mistake #7: Not clarifying reorder timelines and volume commitments

It’s easy to focus on getting the first batch right. But if you plan to reorder, it’s just as important to discuss how the ongoing supply will work.

Without that, several things can go wrong. Reorders may take longer than expected, leading to last-minute shortages. You may be forced to buy at higher prices. Repeat orders may come with higher minimum quantities. Supplier capacity may be stretched in peak seasons.

All of these can create unnecessary hassle. You can avoid that by setting the standard lead time for repeat orders. Confirm minimums for each reorder. Ask if SKUs can be bundled together. Also, find out if the supplier can handle sudden surges in demand.

Final thoughts

Ready to make the switch to compostable bags? Make sure you avoid the mistakes I have highlighted above.

Gather clear specs, request certification for the finished product, and compare costs per piece, not per kilo. Build relationships with suppliers based on total volume and shared standards. Define quality and reorder expectations from day one.

Most importantly, see sourcing as something that evolves over time. Each order helps you refine the process.